Basic Info.

Model NO.

Customized logo

Certification

CE

Scale

Large

Automation

Automatic

Principle

Immersion

Structure

Tunnel

Operation

Continuous

Energy

Heat Sterilization

Property

Physical Sterilization

Type

High Voltage Electric Field Sterilization Equipment

Product Name

Water Immersion Pressure Retort Machine for Vacuum

Sterilizing Way

Water Bathe Retort

Heating Way

Water Heating Autoclave Retort

Control System

Automatic Autoclave Retort

Apply to

Retort for Food,Meet,Vegetable,Beverage,Cans

Function

Sterilization for Autoclave Sterilizer

Processing Types

Sterilizing Packing Canned

Design Temperature

147 Degree Autoclave Sterilizer

Usage

Water Immersion Pressure Retort Machine for Vacuum

Weight

2200 Kg

Core Components

Pressure Vessel

Transport Package

Naked

Specification

2700*2100*2500

Trademark

Mosen

Origin

China

Production Capacity

600sets

Packaging & Delivery

Package Size

36.00cm * 28.00cm * 6.00cm

Package Gross Weight

2.000kg

Product Description

Automatic Water immersion pressure retort machine for food in cans and pouches food sterilization retort autoclave machine

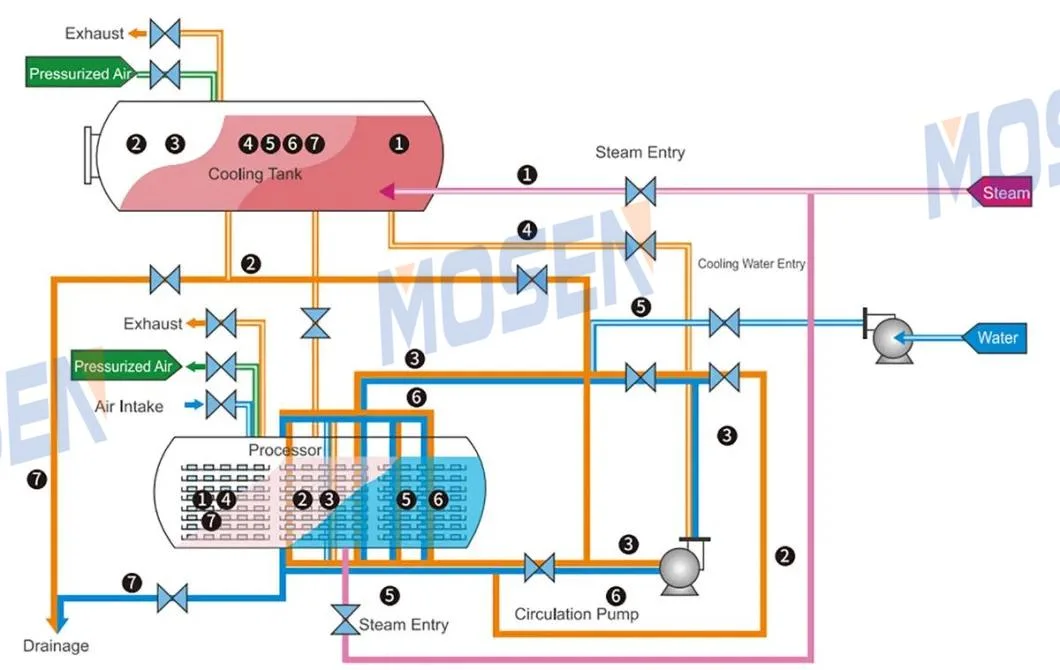

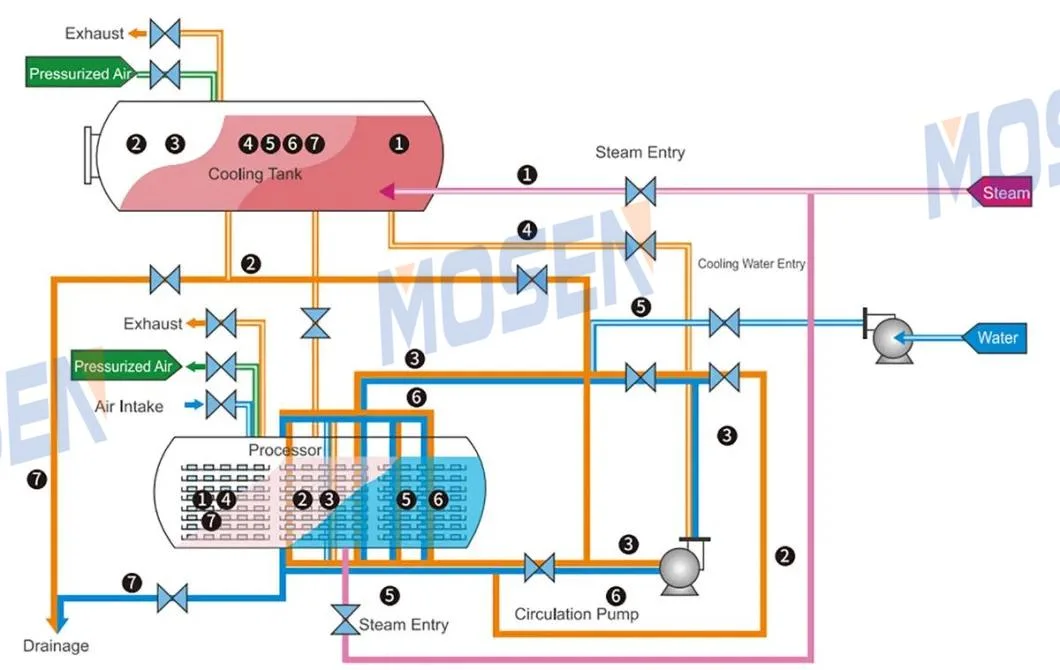

1 .water bath retort is composed of two tanks. Hot water store in tank and temperature

reset. Soft water with recycle work to save energy and water resource.

2 .water retort using circulate water and continuous steam supply ensure the temperature

rror within 5° for all bathed products.

3 water retort temperature of circulating water is uniformly and stable under the dual

unction of top tank preheating, circulation pump and steam.

Specification

Component

Automatic Water immersion pressure retort machine for food in cans and

pouches food sterilization retort autoclave machineHow to work

Application

Why Choose Us

Why Choose Us

Our company, Shandong Mosen Machinery Co.,Ltd is a subsidiary of Mosen Industry. It is a manufacturer

of pressure vessels for food sterilization retort, food jacketed cooker, vacuum cooker, etc. Our company

integrates scientific research, production, sales and service. Our company has been committed to the

development trend of pressure vessels for many years, saving manpower, improving qualified production

rate and reducing production cost through automation design and manufacturing.

Our company has various talents such as machinery manufacturing, food, rubber technology, engineering

installation,etc., and has built a team of comprehensive services to strive to contribute perfect service.

After-sales Service

1. One-year Warranty

Our company implements a one-year warranty for the products.

2. About the equipment

If the device fails or encounters difficult problems during use, you can first solve it by reading the common

troubleshooting

method in the product description.

3. About Delivery

Before delivery, our professional technician will do trial run for each product to check until everything is

functional, you also

can come to our factory and test our machine together with us.

When loading, our engineers will fix the retorts tightly with wire rope so that the retorts can't move in

the container.

Our factory has passed the GB150-2011 system certification and obtained the GB150-2011 certificate.

Our quality management is carried out in strict accordance with this standard;

Our factory has passed the review of Pressure Vessel Association, the CE certificate, and the factory

has passed the review of ASME joint inspection team and obtained ASME standard; At the same time,

we pay attention to the health and safety of employees in strict accordance with international practices.

Certificate

Certificate

Our factory has passed the review of Pressure Vessel Association, the CE certificate, and the factory

has passed the review of ASME joint inspection team and obtained ASME standard; At the same time,

we pay attention to the health and safety of employees in strict accordance with international practices.

1 .water bath retort is composed of two tanks. Hot water store in tank and temperature

reset. Soft water with recycle work to save energy and water resource.

2 .water retort using circulate water and continuous steam supply ensure the temperature

rror within 5° for all bathed products.

3 water retort temperature of circulating water is uniformly and stable under the dual

unction of top tank preheating, circulation pump and steam.

Specification

Specification

| Model | Outside measurement(mm) | Inner diameter (mm) | Length (mm) | Capacity (m³) | Pot thickness(m) | Temperature (ºC) | Pressure (Mpa) | Weight (kg) | Operating weight(kg) | Voltage (V) | Power (kw) | ||

| length | width | hight | |||||||||||

| PLJ.10-1.B.3 | 1885 | 1200 | 1458 | 1000 | 950 | 1.00 | 4 | 147 | 0.3 | 560 | 860 | 380 | 3.5 |

| PLJ.10-2.B.3 | 2970 | 1200 | 1458 | 1000 | 1900 | 1.80 | 4 | 147 | 0.3 | 650 | 1250 | 380 | 6 |

| PLJ.12-2.B.3 | 3102 | 1500 | 1660 | 1200 | 1900 | 2.60 | 5 | 147 | 0.3 | 860 | 1400 | 380 | 6 |

| PLJ.12-3.B.3 | 4100 | 1500 | 1780 | 1200 | 2870 | 3.70 | 5 | 147 | 0.3 | 1200 | 1800 | 380 | 11.5 |

| PLJ.12-3.6B.3 | 4938 | 1500 | 1660 | 1200 | 3820 | 4.06 | 5 | 147 | 0.3 | 1300 | 2100 | 380 | 11.5 |

| PLJ.14-3.B.3 | 4938 | 1600 | 1880 | 1300 | 4000 | 5.62 | 5 | 147 | 0.3 | 1500 | 2300 | 380 | 23 |

Component

Automatic Water immersion pressure retort machine for food in cans and

pouches food sterilization retort autoclave machineHow to work

Application

Why Choose Us

Why Choose Us Our company, Shandong Mosen Machinery Co.,Ltd is a subsidiary of Mosen Industry. It is a manufacturer

of pressure vessels for food sterilization retort, food jacketed cooker, vacuum cooker, etc. Our company

integrates scientific research, production, sales and service. Our company has been committed to the

development trend of pressure vessels for many years, saving manpower, improving qualified production

rate and reducing production cost through automation design and manufacturing.

Our company has various talents such as machinery manufacturing, food, rubber technology, engineering

installation,etc., and has built a team of comprehensive services to strive to contribute perfect service.

After-sales Service

1. One-year Warranty

Our company implements a one-year warranty for the products.

2. About the equipment

If the device fails or encounters difficult problems during use, you can first solve it by reading the common

troubleshooting

method in the product description.

3. About Delivery

Before delivery, our professional technician will do trial run for each product to check until everything is

functional, you also

can come to our factory and test our machine together with us.

When loading, our engineers will fix the retorts tightly with wire rope so that the retorts can't move in

the container.

Our factory has passed the GB150-2011 system certification and obtained the GB150-2011 certificate.

Our quality management is carried out in strict accordance with this standard;

Our factory has passed the review of Pressure Vessel Association, the CE certificate, and the factory

has passed the review of ASME joint inspection team and obtained ASME standard; At the same time,

we pay attention to the health and safety of employees in strict accordance with international practices.

Certificate

Certificate Our factory has passed the review of Pressure Vessel Association, the CE certificate, and the factory

has passed the review of ASME joint inspection team and obtained ASME standard; At the same time,

we pay attention to the health and safety of employees in strict accordance with international practices.